Blog

How to overcome the 5 biggest pain points in warehousing

A warehouse is, as you probably know from experience, a vast network of tiny moving parts, scan beeps, pallets, orders, and more. To have happy customers, you have to consider your warehouse operations in a way which is organized and can both dispatch orders on time and fulfill returns in an appropriate fashion; this can range anywhere from traffic management to labor, from software to hardware. Here are the top 5 warehousing pain points we’ve observed – and how you can avoid them:

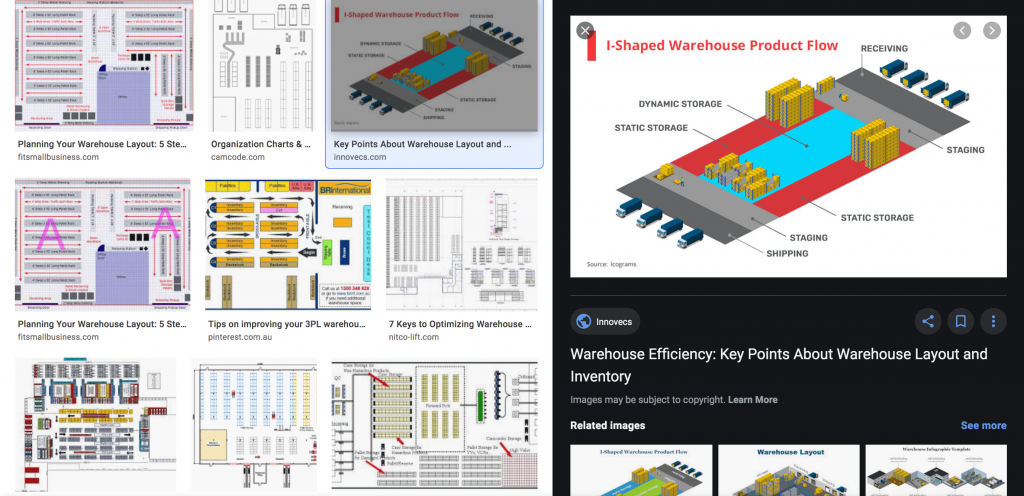

Inefficient warehouse layout

Think about the way your warehouse is designed. Does it look like it was designed by a civil engineer who understands principles of traffic flow, takes strict measurements, and makes sure every vehicle and case can be stored optimally? Or is it closer to hoarding but with some basic shelving and labels? If you’re thinking the latter, you may want to consider a layout update. Warehouse layouts “must be modular, adaptable, compact, and accessible and must be capable to respond to changing conditions…sometimes, trade-offs must be made between conflicting objectives” (Geraldes, Carvalho, et al).

Answer some key questions for yourself, like: are my employees zig-zagging too much, and can I restructure things to send them on a straight path to the shipping lane? Would it be better to store perishable items away from doorways, or if a product is seasonal a sells quickly, would it actually be better to position it closest to the main sources of traffic? You’ll save time and money taking a hard look at your floor plan and maybe even making some changes.

Inefficient picking/packing processes

When you were first starting your warehouse, you probably sought some sort of guidance on picking and discovered, very quickly, the complete lack of standard process. Unfortunately we’re frequently on our own when it comes to warehouse picking best practices, and we may often develop a system that’s inefficient. Items often end up in the wrong location, pickers pick the wrong item altogether, and multiple people can cause chaos – along with a litany of other potential issues. Picking and packing is probably around half your operation anyway; why not look to improve?

There are a few ways to make the operation more lean and effective. First, consider an easy-to-use warehouse management system. Software that doesn’t come with the baggage of a difficult learning curve can empower employees to teach each other – and makes temporary/seasonal work a breeze. You’ll save time and sweat on training alone! Second, make sure your process is logical. Second, ensure accountability. When you have people out on the floor making decisions, you want to have the ability to identify kinks in the machine and make corrections for the good of the team, so always know who’s done what. And last, keep shelving orderly and clean! A cluttered world makes for a cluttered brain.

Inventory shrink/poor inventory management

Oh, this is everyone’s favorite. How often has this happened to you: you sell something on one e-commerce channel, but there’s nothing to automatically decrement that inventory from another e-commerce channel, and then you forget all about it, resulting in a sudden stockout and delays in service? Worst of all, that sync button that some inventory management systems claim to have down perfectly is terrible IRL. And then there are the unlikely but logical worries: theft, accidents…

One thing is for certain: although there are always bound to be problems you can’t control, your software must not make the problem worse – so look for a system that adjusts omnichannel inventory in real time. Ensure there are safety, security, and ergonomics precautions taken to prevent workplace/retail breakage or stealing. And finally, use predictive analytics and continuously updating business insights to see stockouts way before they hit you – and double check everything’s on track in case on hits you by surprise.

Failing to prioritize return flow

Returns are often a tertiary consideration when thinking about warehouse spaces. The logical flow of a warehouse in an ideal business scenario is receive-pick-ship; you might assume that returns will never happen or deprioritize them because you’re just so damn good at what you do. Wrong! Proper return and refund procedure is the cornerstone to preventing customer attrition in case one particular experience doesn’t work out the way you hoped. Getting items back in and restocking as quickly as possible means you can have speedy communication with the customer about their refund – and that customer lifetime value still has a great chance of increasing.

So consider your procedure: what happens to a returned package? Is there a form to fill out? Is there a restocking fee? Do your books have to be adjusted if the product is damaged or required refurbishment? Do you have adequate space to process a ton of returns at once, in case a particular day goes horribly wrong? And – as mentioned above – how does the returns space fit into your overall warehouse plan? Answering those questions and addressing relevant issues with due consideration will give your operations a leg up over the competition.

Low morale

Human labor is dynamic— and because you just can’t automate everything, it’s here to stay. Manual labor is tough, and low morale can lead to – you already know the list – bad work, absence, turnover, insubordination, blah, blah, blah. Avoid it. Be nice to your employees. Do things for them to remind them you care.

Here are a few examples of things you can do that will tangibly improve your staff’s outlook: first, make them take breaks. Yes, 2020 corporate culture might tempt you to punish employees who are neurotically above and beyond, but investing in process and procedure could save you the time that you’d normally expect employees to work through! Create a culture that makes them want to be there. Inexpensive employee outings, summer Fridays, all of that stuff… it’s proven to work. Celebrate a milestone with a cake. What’s it cost anyway, 15 bucks? Make collaboration a two-way street. If you’re looking for insight into their daily experience, why not just ask? If you’re looking for ways in which things could be improved, there is no better person to get feedback from than the one who experiences that task or procedure firsthand on a daily basis. Plus, staff who are consulted will feel like they have a more personal stake in the affairs of your business.

(Oh, and spend that extra money on frequent deep cleans of the facility, since we’re mid-pandemic and all. Don’t want half your crew getting sick!)

Getting a grip on these points of tension will make your business so much more successful – but we know there are always issues that may be unforeseen and may require new solutions. Contact us if you ever have any questions about our products or a general inquiry. We’ll get back to you ASAP!

-The CB Team