What Q4 Reveals About Your Warehouse Operations

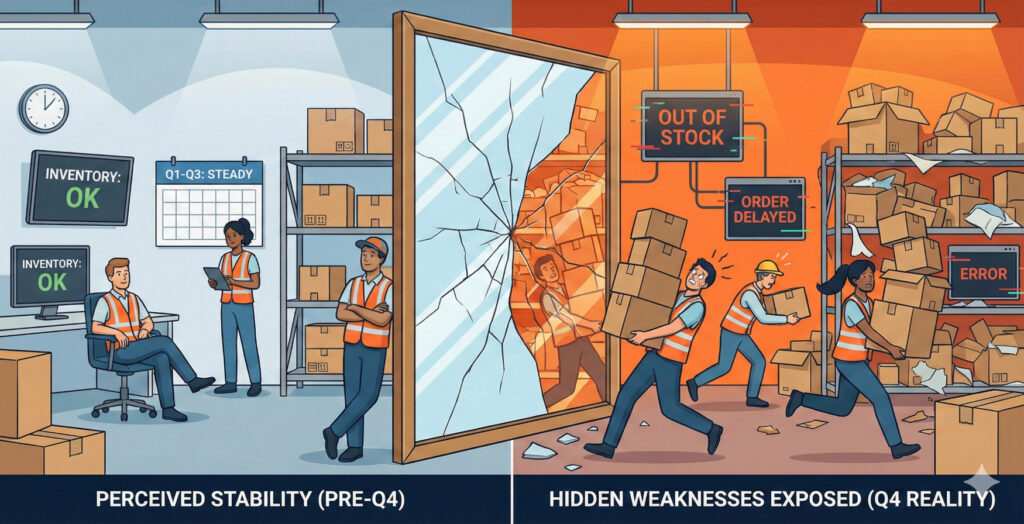

Every year, Q4 arrives with the same promise and the same threat. Higher demand. Higher expectations. Higher pressure. For many teams, it is the busiest and most stressful time of the year. For warehouse operations, Q4 is not just a peak season. It is a mirror. And it does not lie.

The reality is that Q4 does not create problems in your warehouse. It exposes the ones that have been quietly building all year long. The processes that felt acceptable when volume was steady suddenly crack under pressure. The workarounds that teams rely on become bottlenecks. The data gaps that were easy to ignore turn into costly mistakes. By the time Q4 is in full swing, there is no room to hide. Everything shows.

What makes Q4 so revealing is that it compresses time. Orders move faster. Inventory turns quicker. Decisions have to be made immediately. When your warehouse operations are strong, Q4 feels intense but controlled. When they are not, it feels chaotic, reactive, and exhausting.

One of the first things Q4 reveals is how well your inventory data actually reflects reality. Many warehouses operate comfortably throughout the year with inventory counts that are slightly off. A few units missing here, a few extra there. During normal months, those inaccuracies rarely cause visible damage. In Q4, they become disasters. Overselling spikes. Orders get split or delayed. Customer service tickets pile up. Suddenly everyone is questioning why the system says stock is available when the shelf is empty.

This is usually not a people problem. It is a visibility problem. Q4 highlights whether your inventory is being updated in real time, whether stock movements are consistently recorded, and whether all sales channels are actually pulling from the same source of truth. If your warehouse relies on manual updates, delayed syncs, or separate systems talking to each other imperfectly, Q4 will make that painfully obvious.

Another thing Q4 reveals is how dependent your operations are on tribal knowledge. Many warehouses run smoothly because a few experienced people know how things really work. They know which orders need special handling. They know which SKUs are problematic. They know which shortcuts to take when things get busy. During Q4, when volume surges and absences happen, those invisible dependencies surface. When one key person is unavailable, the entire operation slows down. This is where process documentation and system-driven workflows stop being nice to have and start being essential. Q4 exposes whether your warehouse can function consistently regardless of who is on shift. If tasks are not standardized, if priorities are not clearly defined in the system, and if exceptions are handled ad hoc, Q4 magnifies every inconsistency.

Order management is another area where Q4 tells the truth. During slower months, it is easy to get away with manual order checks, partial automation, or delayed releases. In Q4, order volume increases while customer patience decreases. Late shipments, missed cutoffs, and unfulfilled promises are no longer small issues. They directly impact brand trust and revenue. Q4 reveals whether your order flow is designed to scale or just survive.

Are orders automatically routed to the right warehouse or fulfillment method? Are priority orders clearly identified? Can your team see order status at a glance without jumping between systems? When questions arise, is the answer immediately visible or buried somewhere in a spreadsheet or inbox?

Returns also behave differently in Q4. Many warehouses treat returns as a secondary process, something to deal with later. Q4 does not allow that luxury. Returns spike, space gets tight, and inventory that could be resold sits unprocessed. This reveals whether your warehouse has a clear, efficient return workflow or whether returns are handled reactively whenever someone finds the time.

The way your warehouse handles peak returns says a lot about how well your operations are integrated. If returned inventory does not flow back into available stock quickly and accurately, you lose sales opportunities precisely when demand is highest. Q4 makes the cost of slow return processing impossible to ignore.

Q4 also reveals how flexible your warehouse actually is. Many teams believe they are adaptable until they need to adjust quickly. A sudden promotion. A channel surge. A carrier delay. A supplier issue. In Q4, these are not rare events. They are daily occurrences. Warehouses that rely on rigid processes or disconnected systems struggle to respond. Teams end up firefighting instead of managing. Flexibility does not mean chaos. It means having systems that allow you to adjust rules, priorities, and workflows without breaking everything else. Q4 shows whether your warehouse technology supports change or resists it.

Perhaps the most important thing Q4 reveals is how much stress your operations place on your people. Long hours, constant urgency, and unclear priorities burn teams out fast. If your warehouse relies on heroics to get through Q4, that is not a sustainable model. It might work once. It might even work for several years. But Q4 keeps score. Eventually, the cost shows up as errors, turnover, and lost momentum. When operations are supported by clear workflows, accurate data, and systems that do the heavy lifting, Q4 is still demanding, but it is manageable. Teams know what to do. They trust the data. They can focus on execution instead of constant problem-solving.

This is why Q4 is such a valuable diagnostic tool. It forces you to confront the reality of your warehouse operations. Not in theory. Not in planning documents. In real time, under pressure, with real consequences. The mistake many businesses make is treating Q4 as something to survive and then forget. The smarter approach is to treat it as feedback. Everything that felt painful, slow, or risky during Q4 is telling you exactly where your operation needs attention. Those insights are far more valuable than any internal audit or consultant report.

Platforms like CommerceBlitz OMNI exist because these challenges are not unique. They repeat every year, across warehouses of all sizes, across brands, retailers, and 3PLs. Centralized inventory visibility, scalable order management, clear workflows, and real-time data are not just Q4 tools. They are foundations that make Q4 predictable instead of chaotic.

When your warehouse is built on systems that scale, Q4 stops being a stress test and starts being an opportunity. An opportunity to move faster than competitors. An opportunity to fulfill promises confidently. An opportunity to finish the year strong instead of exhausted.

Q4 will always reveal the truth about your warehouse operations. The only question is whether you use that truth to improve or ignore it until next year exposes the same problems all over again.

If you want to see how your operations could look with real visibility, automation, and control in place before the next peak hits, schedule a CommerceBlitz OMNI demo. It is far better to learn from Q4 while the pressure is fresh than to repeat the same lessons when the stakes are even higher.