Scaling Your Warehouse Temporarily for Holiday Demand

Every year, the same pattern repeats itself. Forecasts look optimistic, sales teams prepare promotions, marketing calendars fill up, and then the warehouse quietly becomes the pressure point no one wants to talk about. Holiday demand does not fail because people stop buying. It fails because operations are asked to stretch further than they were designed to, often with very little warning and even less room for error.

Temporary scaling is one of the hardest challenges in warehouse operations because it sits in an uncomfortable middle ground. You are not building for long-term expansion, yet the consequences of getting it wrong feel permanent. Late shipments, inventory inaccuracies, exhausted staff, and frustrated customers do not reset automatically when the holidays end. They leave behind damaged trust and operational debt that takes months to unwind.

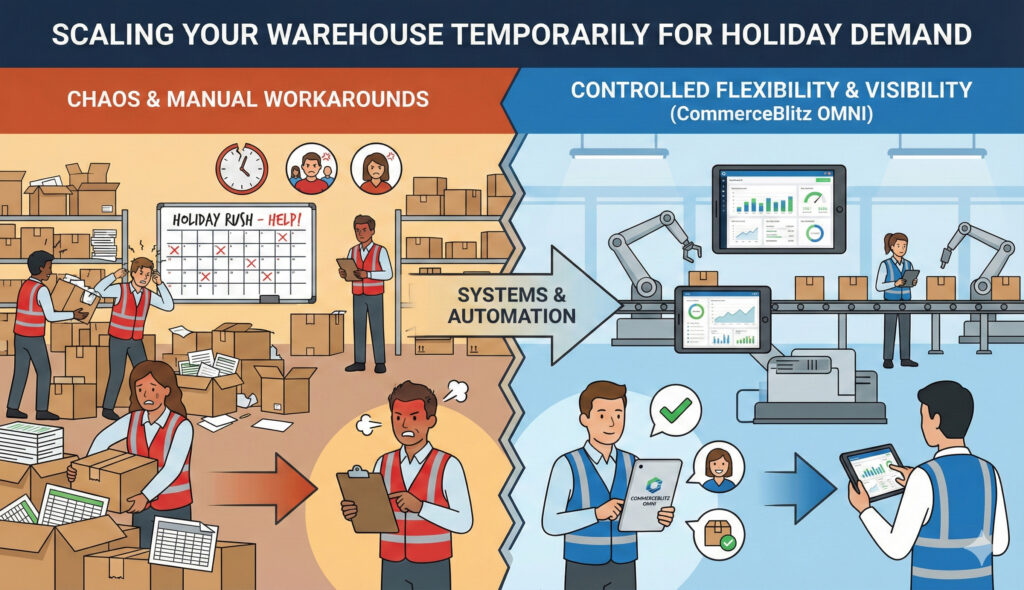

The key to scaling successfully for peak season is understanding that temporary does not mean improvised. It means controlled flexibility, supported by systems, processes, and visibility that can absorb pressure without breaking.

Holiday volume does not only increase order counts. It changes order behavior. You see more single-line orders, more gift-driven SKUs, more split shipments, and more time-sensitive fulfillment expectations. Carriers become less predictable. Cutoff times shrink. Returns spike almost immediately after the peak. All of this compounds inside the warehouse, often at the same time seasonal labor is being onboarded and trained.

One of the biggest mistakes teams make is assuming that temporary scale can be handled with spreadsheets, manual workarounds, and heroic effort from staff. That approach can survive a mild spike. It collapses under sustained holiday pressure because every manual process becomes a bottleneck multiplied by volume. Picking errors increase. Inventory confidence drops. Supervisors spend their days firefighting instead of managing flow.

Successful temporary scaling starts with clarity. You need to know which SKUs will drive volume, which orders generate the most operational complexity, and which parts of your workflow are already close to capacity. This is not guesswork. It requires historical data, clean order information, and real-time inventory visibility. Without that foundation, every decision you make during peak season is reactive by default.

Labor is usually the first lever companies try to pull. Hiring temporary staff can help, but only if your processes are simple enough to absorb them quickly. When workflows are unclear or constantly changing, new staff slow the operation instead of accelerating it. Training becomes rushed, mistakes increase, and experienced workers spend more time correcting errors than moving orders out the door. This is why process standardization matters even more during temporary scale. Pick paths should be predictable. Packing rules should be clear. Exception handling should follow defined logic instead of individual judgment calls. The more decisions your system can make automatically, the more capacity you free up from your people.

Space is another silent constraint during the holidays. Pallet locations fill faster, staging areas become congested, and temporary overflow storage appears wherever there is room. Without accurate location tracking and inventory updates, warehouses quickly lose confidence in where product actually lives. That loss of confidence slows everything else down, from picking to cycle counts to replenishment.

Temporary scale demands temporary flexibility in how inventory is managed, but not in how it is tracked. This is where many operations struggle. They allow shortcuts in receiving, skip scans, or delay updates to keep things moving. In the short term, it feels faster. In reality, it creates a fog that only thickens as volume increases.

Order orchestration also becomes more complex during peak season. You may need to prioritize certain channels, split orders differently, or adjust fulfillment rules to meet carrier cutoffs. If these decisions live in people’s heads instead of in your system, consistency disappears the moment someone is unavailable or overwhelmed.

This is where an OMS and WMS working together becomes critical. Temporary scaling is not just about moving faster. It is about making smarter decisions under pressure. When order routing, inventory availability, and fulfillment logic are centralized, the warehouse can respond dynamically without chaos.

CommerceBlitz OMNI was designed with this exact challenge in mind. During peak periods, OMNI allows teams to maintain visibility across orders, inventory, and warehouse activity in real time, even as volume fluctuates. Instead of layering manual fixes on top of broken workflows, operations teams can rely on system-driven logic to prioritize, route, and execute orders consistently.

Another often overlooked aspect of holiday scaling is communication. When visibility is limited, teams spend valuable time asking questions instead of fulfilling orders. Where is this SKU. Why is this order delayed. Did this shipment go out. Each question interrupts flow. Each interruption compounds across hundreds or thousands of orders. Clear dashboards, shared views, and accurate status updates reduce noise dramatically. They allow supervisors to manage by exception instead of micromanaging every step. They also reduce stress across the organization, from customer support to leadership, because everyone sees the same version of reality.

It is also important to plan for the end of peak season while you are still in it. Returns processing, inventory reconciliation, and post-holiday reporting can overwhelm teams if all attention is focused solely on outbound volume. Temporary scale without a controlled unwind creates a second crisis just as teams are already exhausted.

The most resilient warehouses treat holiday demand as a stress test, not a survival test. They use it to identify where automation helps most, where visibility breaks down, and where systems either support or hinder decision-making. The goal is not to survive at any cost. It is to emerge stronger, with clearer insight into what true scalability requires.

Temporary scaling will always be challenging. But it does not have to be chaotic. With the right systems, clear processes, and real-time visibility, warehouses can flex for peak demand without sacrificing accuracy, trust, or team morale.

If you want to see how CommerceBlitz OMNI supports temporary scaling during high-demand periods while keeping operations stable and visible, you can schedule a walkthrough with our team. It is the fastest way to understand how controlled flexibility can replace holiday chaos.